16th Jan 2025

PVC vs. CPVC Pipes: What Are the Differences?

Selecting the right pipes for plumbing projects is one of the most pivotal decisions contractors, builders, and plumbers make. Pipes are more than just vessels transporting water or other fluids—they are the backbone of any plumbing system. Choosing incorrectly can result in costly repairs, inefficiencies, or even safety hazards down the line.

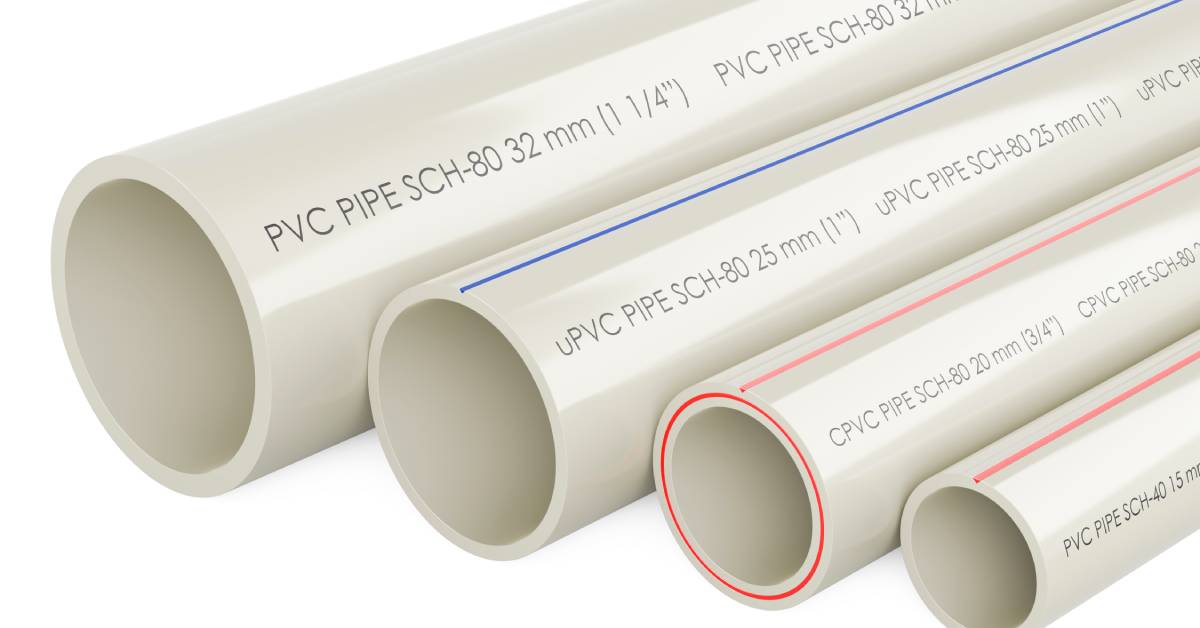

Among the many choices available, PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) pipes often emerge as popular contenders. But how do you decide between the two? Let’s take a deep dive into the differences between PVC and CPVC pipes so you can always find the right option for the next job.

How They Work

To begin, it’s crucial to understand what PVC pipes and CPVC pipes are and why they are so widely used. PVC, or Polyvinyl Chloride, is one of the most common thermoplastic materials used in a variety of industries. Known for being durable, lightweight, and easy to work with, PVC pipes are frequently used in plumbing, irrigation, and even some structural applications. They are especially popular for cold-water systems due to their resistance to corrosion and affordability, though their pressure ratings and heat thresholds can vary depending on the schedule, such as Schedule 40 PVC pipe or Schedule 80 PVC pipe fittings.

Improving Performance With CPVC

CPVC, or Chlorinated Polyvinyl Chloride, is essentially an upgraded version of PVC. The additional chlorination process enhances the material’s resistance to higher temperatures of up to 200°F, making it ideal as well as code required for carrying hot water or handling more demanding chemical environments.

Like PVC, CPVC is highly durable but plays a specific role in applications where heat resistance is a key consideration. It finds usage in residential and commercial hot water systems, industrial pipelines, and anywhere chemical robustness is a priority. It’s important to note that CPVC is not interchangeable with PVC fittings or PVC cement, as using the wrong type can compromise the system’s integrity and safety.

Differences Between PVC and CPVC Pipes

When it comes to PVC and CPVC pipes, identifying what the differences are is invaluable to the long-term success of the system you’re building, whether for irrigation or another application entirely.

While PVC and CPVC appear similar to the untrained eye, there are several key differences that set them apart. At their core, the material composition of the two varies significantly due to the additional chlorination process used in producing CPVC.

This slight alteration enhances CPVC’s ability to withstand higher temperatures. PVC is generally rated for temperatures up to 140°F, while CPVC extends that capability to approximately 200°F. This disparity often determines which material is chosen for applications that involve hot water transport or processing environments.

Building Dependable Systems

Another major difference lies in their chemical resistance. While PVC is impressive in handling many non-corrosive chemicals, CPVC steps up the game, tolerating a broader array of chemicals without degradation. This makes CPVC suitable for industrial systems or environments where strong chemicals are present.

The selection between PVC and CPVC is also influenced by building codes and project requirements. Many regulations clearly outline where each type can or cannot be used based on safety considerations. For example, some areas strictly mandate CPVC for hot water lines in residential settings.

Advantages and Disadvantages

PVC Advantages:

- Affordable and versatile

- Lightweight

- Easy to transport and install

- Lower labor costs

- Corrosion-resistant in outdoor or underground applications

- Smooth interior reduces friction, improving flow efficiency

- Long service life in cold and moderate temperature applications

- Widely available and easy to source

PVC Disadvantages:

- Lower temperature tolerance

- Lower level of chemical resistance compared to CPVC

- Can become brittle over time when exposed to UV light without protection

- Not suitable for hot water applications

- Less impact-resistant in extremely cold conditions

CPVC Advantages:

- High heat tolerance

- Strong chemical resistance

- Can be used for both hot and cold water applications

- Durable and long-lasting in demanding environments

- Smooth interior helps maintain water pressure and flow

CPVC Disadvantages:

- Higher material cost

- More rigid than PVC

- Requires specific cement and fittings

- Slightly heavier than PVC

- Can be more prone to cracking if stressed during installation

Essential Deciding Factors

The scope of the project is key—consider what the pipes will be transporting and under what conditions. For cold-water systems or basic drainage, PVC is typically an efficient and economical choice. For hot water systems, CPVC is the clear winner due to its ability to withstand higher temperatures.

Budget constraints also play a significant role. If cost is a concern and the project requirements don’t necessitate heat or chemical resistance, PVC provides excellent value for money. However, when safety or longevity under demanding conditions is paramount, CPVC is a worthwhile investment.

For outdoor or exposed projects, the pipe’s resistance to UV light, freezing temperatures, and other natural elements could influence the decision. Understanding local building codes is essential as well, as they might mandate compliance to specific material standards.

Ensuring a Successful Installation

Knowing how to install both PVC and CPVC is critical because not only are both options reliable in the right applications, but they are each impressively versatile. For example, at Maxx Supply, our inventory of CPVC plumbing fittings includes elbows, tees, unions, couplings, caps, and many more components.

Ensuring the successful installation of PVC and CPVC pipes requires careful planning and adherence to proper methods. Cutting the pipe to the correct length should always result in clean, smooth edges to prevent leaks during assembly. Special tools tailored for PVC and CPVC are widely available and relatively inexpensive.

Joining the pipes involves proper application of primers and solvent cement to create secure, watertight seals. For added leak protection, some installers also use compatible pipe sealants on threaded joints or fittings. Here is where the primary difference between PVC and CPVC again becomes apparent using the correct solvent cement rated for each material is critical. CPVC, for instance, requires a solvent specifically designed to cater to its chemical composition. Using the incorrect cement for your PVC or CPVC pipes can cause significant damage, such as joint failure.

Furthermore, supporting the pipes appropriately during installation is critical to their longer lifespan. Overlooked supports or improper spacing can lead to sagging or even fractures, particularly in systems that experience high flow rates or elevated temperatures.

Choosing the Right Pipes

PVC and CPVC are both excellent options for a range of plumbing and industrial applications, offering unique properties that cater to different project needs. Choosing the right pipe not only delivers immediate benefits in terms of functionality but also contributes to the long-term success of the project.

Focus on these key details so you can create a system that is durable, efficient, and suited to its intended purpose. Always take the time to evaluate the specifications and environment in which the materials will be consistently used for the best results.