19th Mar 2025

Using PVC in HVAC Systems: What Contractors Should Know

PVC, or polyvinyl chloride, has carved out a significant role in various industries, and the world of HVAC systems is no exception. For HVAC contractors, understanding the uses and benefits of PVC can make design and installation processes more efficient and cost-effective.

It’s important to know the key advantages, best practices, challenges, and other key details before incorporating PVC into HVAC systems. We’re ready to give contractors the knowledge they need to take full advantage of this versatile material. Get a closer look at what contractors should know about using PVC in HVAC systems so that you can always achieve a smooth performance.

The Role of PVC in HVAC Systems

PVC is a popular choice across the construction and engineering fields due to its durability, light weight nature, and affordability.

Within HVAC systems, professionals typically turn to PVC for ductwork and condensate drainage systems. Its corrosion resistance makes it especially valuable in environments where moisture or chemicals might otherwise compromise the integrity of metal components.

Replacing traditional materials like metal with PVC in certain applications will help contractors achieve a balance of durability and cost-effectiveness. However, using it properly in HVAC systems requires a solid understanding of its strengths and limitations.

Why PVC Stands Out in HVAC Applications

PVC has gradually become a preferred material in HVAC installations for several reasons, starting with its superior resistance to environmental factors. Unlike metals, PVC doesn’t corrode when exposed to damp conditions or chemicals, making it a reliable choice for condensate drains and exhaust venting.

The lightweight nature of PVC also eases the burden of transportation and installation, reducing time and labor costs for contractors. Its smooth interior surface minimizes fluid friction, which promotes efficient airflow and liquid drainage—crucial factors for effective HVAC system performance.

Another compelling benefit is PVC’s affordability. Compared to metals like galvanized steel or aluminum, PVC offers a budget-friendly alternative without compromising on safety or functionality. This cost-saving benefit is particularly appealing for residential and light commercial installations.

Ensuring Proper Installation of PVC in HVAC Systems

Installing PVC in HVAC applications requires precise planning and adherence to industry standards to ensure long-term performance. When implementing PVC, contractors should always account for factors like the application’s mechanical load and operating temperature. While PVC is robust, its thermal expansion properties mean it can react to temperature changes, so proper supports and expansion fittings remain critical.

Solvent welding is the primary method for joining PVC components. Applying the correct primer and cement ensures a watertight and durable seal. Contractors should also verify the ventilation of solvent vapors during installation and check all joints to mitigate the risk of leaks.

One key consideration is properly labeling PVC pipes to meet local codes and clarify their purpose in condensate removal or air venting. Professionals must also regularly inspect HVAC systems to ensure that PVC components continue to perform optimally without signs of wear or damage.

Addressing Challenges When Using PVC

Despite its advantages, PVC presents some challenges that HVAC contractors must address. Temperature limitations remain one concern; PVC is not ideal for high-temperature applications, as excessive heat can cause it to warp or lose strength.

CPVC, a variant of PVC designed for higher operating temperatures, is a better option for exhaust venting of high-efficiency furnaces or boilers that produce hot gases.

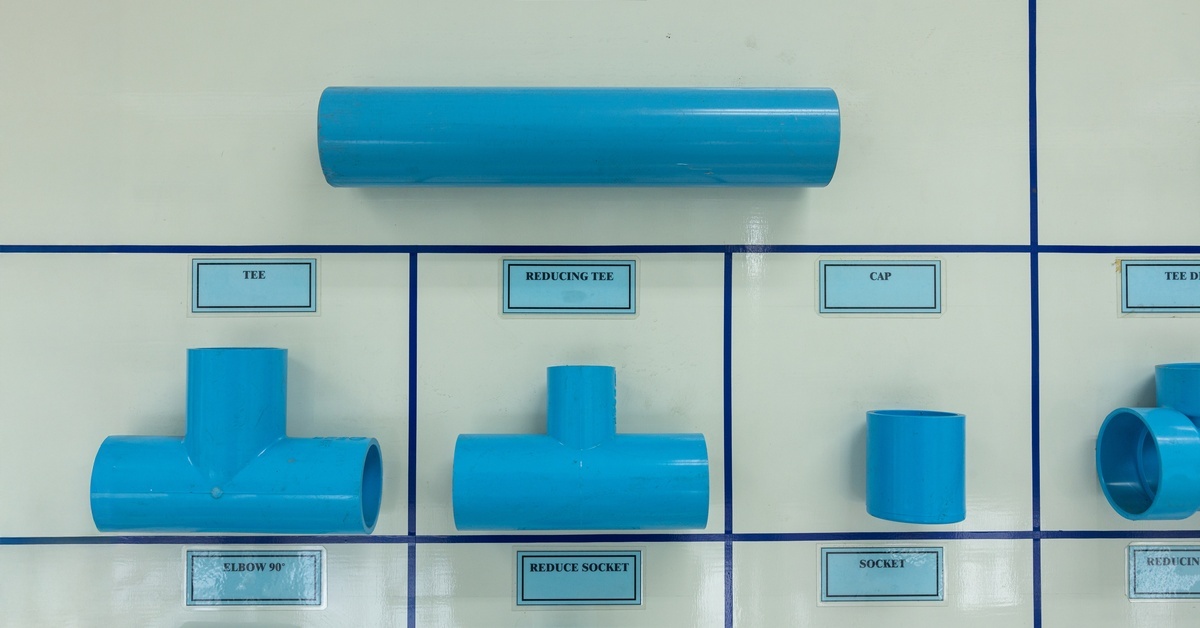

UV degradation is another consideration for outdoor applications. Prolonged exposure to sunlight can weaken PVC components, so it’s essential to select UV-resistant coatings or add protective shielding where necessary. Pay attention to schedule numbers for PVC fittings to ensure the best performance in your system. For example, you can shop for schedule 80 PVC pipe fittingsthat feature thicker walls and superior strength to their schedule 40 counterparts.

When it comes to sound insulation, metal ductwork often outperforms PVC. Contractors can use soundproofing wraps or barriers to dampen vibrations in PVC air distribution systems and minimize noise. By proactively addressing these challenges, contractors can ensure that their installations maintain reliability and customer satisfaction.

Shopping for PVC for HVAC Systems

Evaluating what contractors should know about using PVC in HVAC systems also requires breaking down the key steps for buying PVC.

First, it’s important to understand the type of PVC required for HVAC applications. Standard PVC pipes and fittings are often suitable for condensate drainage, but certain HVAC projects may demand specialized PVC, such as CPVC (chlorinated polyvinyl chloride). As mentioned above, this material can withstand higher temperatures and is more resistant to chemical degradation. Knowing the operational parameters of your system, such as temperature ranges and exposure to chemicals, will guide this decision.

Quality is another significant aspect to evaluate when purchasing PVC components. Sourcing materials from reputable manufacturers ensures reliability, durability, and adherence to industry standards. Look for PVC that meets ASTM (American Society for Testing and Materials) specifications or other relevant standards, as this is a good indicator of performance and safety.

Finding the Right Materials for Your System

Sizing is equally crucial when selecting PVC. HVAC systems often have precise requirements for pipe diameters to maintain proper airflow and optimal drainage. Incorrect sizing can lead to inefficiencies, system strain, or even leaks, which can compromise the longevity and functionality of your system. Always verify the measurements needed for your project, and double-check compatibility with fittings and connections to ensure a seamless installation process.

Accessibility and cost are other components to consider during the purchasing process. PVC’s affordability is one of its biggest draws, but prices can vary depending on sizing, quality, and specialization.

Careful planning and a focus on quality will make shopping for PVC a more efficient and effective process, enabling HVAC contractors to deliver systems that meet and exceed customer expectations. Investing time into selecting the right materials will help contractors enhance the performance and longevity of their HVAC systems while also reducing the likelihood of costly repairs or replacements in the future.

Maximizing Efficiency With PVC

PVC is more than just an affordable material—it’s a tool that allows HVAC contractors to design and install innovative, efficient systems. From condensate drainage to ductwork, PVC offers unparalleled versatility when used strategically and in alignment with best practices.

HVAC contractors who fully understand the benefits and challenges of PVC can guide customers toward optimal solutions that balance performance and cost. With each project, the opportunity exists to refine techniques and apply cutting-edge PVC advancements as they emerge.

Staying informed about installation practices, addressing its limitations, and integrating the latest technology will enable contractors to provide outstanding service while achieving long-term success in their HVAC operations. Take the next step in optimizing your HVAC projects by choosing high-quality PVC products tailored to your needs.