24th Mar 2025

Must-Know Benefits of Flexible PVC vs. PEX Piping

When it comes to modern plumbing and piping solutions, professionals often find themselves choosing between two primary materials: flexible polyvinyl chloride (PVC) and cross-linked polyethylene (PEX). Each has its own strengths, applications, and considerations that make it suitable for particular projects.

With advancements in technology, both options provide durability and cost-efficient solutions, so how do you decide which one is the right fit for your plumbing, building, or maintenance project?

This walkthrough dives deep into the benefits of flexible PVC and PEX piping so you can select the right solution.

Flexible PVC: What You Should Know

Flexible PVC is a versatile piping solution that boasts exceptional strength combined with pliability. Unlike rigid PVC, the flexible variety offers enhanced maneuverability for intricate installations, such as those required in tight spaces or areas with unconventional designs. High-quality flexible PVC is popular in applications like irrigation, drainage, and even pool systems.

One of the biggest advantages of this material is its resistance to moisture, corrosion, and chemical wear. Unlike some materials that degrade when exposed to harsh chemicals or minerals in water, flexible PVC maintains its structural integrity over time for reliable performance.

For professionals prioritizing easy installations without compromising durability, flexible PVC delivers on both fronts. Its compatibility with varied fittings and adaptability across diverse plumbing scenarios make it a go-to choice for many projects.

Exploring PEX Piping

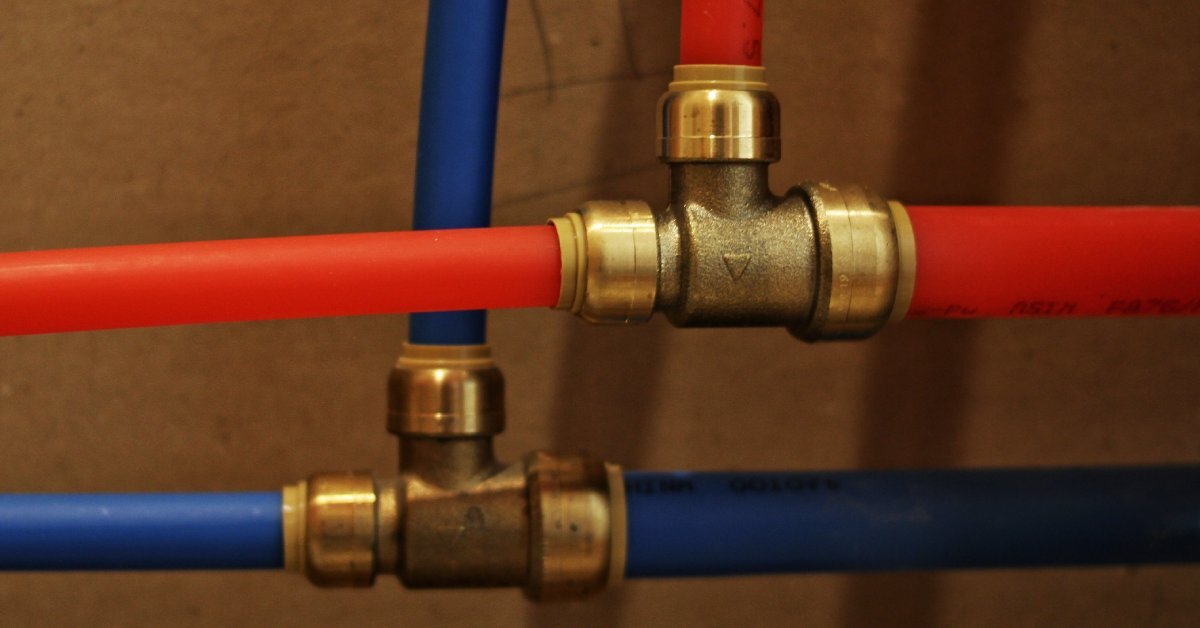

PEX piping has grown immensely in popularity across the plumbing industry. Known for its flexibility and resistance to extreme temperatures, PEX piping is nonmetallic and corrosion-resistant, making it particularly effective in residential applications.

PEX is typically color-coded for hot and cold water lines, simplifying installations and reducing the chances of mistakes during setup. Its lightweight structure makes transportation and handling easy, saving time and labor costs on large-scale projects.

For those working on residential plumbing, PEX is frequently viewed as a highly reliable option. However, understanding how its properties compare to PVC in different scenarios is key before making a final call.

Flexible PVC vs. PEX: A Comparison

Temperature Resistance and Applications

A critical consideration in plumbing and maintenance is how piping materials react to varying temperatures. Flexible PVC offers excellent performance under a wide range of temperatures but is primarily designed for outdoor uses. It holds up well in environments such as irrigation systems and swimming pool applications.

PEX piping, on the other hand, is renowned for its ability to handle extreme temperatures, both hot and cold. This property makes PEX particularly effective for hot water applications and setups that may face freezing temperatures.

Understanding the temperature requirements of your project is crucial for selecting the material that guarantees long-lasting efficiency and fewer maintenance demands.

Installation and Labor Costs

Installation is another factor that often defines the feasibility of a material for a particular project. Flexible PVC, with its robust structure and ease of bending, allows for quicker installation in complex layouts. However, it does typically require solvent welding or clamping mechanisms, which may slightly increase labor time compared to PEX installations.

PEX, by contrast, has become synonymous with simplicity during installation. Its flexibility eliminates the need for numerous fittings and elbows, reducing the time invested in routing and setup.

Labor costs can differ based on the material chosen, but weighing these costs against long-term benefits like durability or reduced maintenance is essential to maximize project efficiency.

Long-Term Durability and Maintenance

Durability is a top concern when selecting piping materials for long-term applications. Flexible PVC, with its resistance to UV rays, chemicals, and mechanical stress, performs brilliantly in outdoor and industrial settings where conditions can be unpredictable. Its long-term resistance to cracking and wear minimizes the need for frequent repair or replacement.

PEX piping provides durability in applications involving water systems but may face degradation when exposed to UV light over long periods. These traits make it less suitable for outdoor installations without added protective measures. Its ability to resist scale buildup and corrosion ensures consistent performance with minimal maintenance over time.

Cost Analysis and ROI

Budget constraints often influence material selection, but the key is balancing upfront costs with long-term returns. Flexible PVC is generally more affordable when considering material costs alone. Its cost-efficiency, combined with durability, makes it ideal for projects requiring sustainable materials at a competitive price point.

PEX may have slightly higher upfront costs, but the savings gained from reduced labor, maintenance, and temperature efficiency may justify the investment over the material’s lifespan, depending on the application.

Ultimately, breaking down costs and potential savings over time reveals which material delivers the best value. Plus, you can explore variations of PVC pipe materials to find a better balance of price and performance capabilities.

For example, choose Class 125 pipe fittingsfor PVC solutions that are more affordable than other classes but provide less strength than its Class 80 or 40 counterparts. Each type of PVC and PEX pipe has its place in the plumbing industry, so make sure to choose the right option for your project.

Regulations and Compliance

Compliance with regulations is critical in plumbing and building applications. Flexible PVC meets industry standards for various residential, commercial, and industrial uses, making it versatile across projects.

PEX is widely accepted as safe for potable water systems and meets numerous regulatory approvals for use in residential and heating applications. Regional building codes can influence material choices, so verifying compliance before installation is essential.

Choosing the Right Material for Your Needs

Evaluating the must-know benefits of flexible PVC and PEX piping will help younavigate every project with a better understanding of how to balance budget, long-term performance, and immediate system requirements.

The debate between flexible PVC and PEX piping ultimately boils down to your specific project needs. Flexible PVC shines in outdoor settings and complex installations, offering great durability and adaptability at an affordable price.

PEX, on the other hand, excels in residential applications and areas with extreme temperature variations, delivering long-term reliability with minimal maintenance. Take the guesswork out of your next project with the right piping materials.