11th Mar 2024

Optimizing Performance: Understanding Pipe Flow Velocity by Size with Maxx Supply

Introduction

In the realm of fluid transportation systems, efficiency reigns supreme. Every drop of liquid counts, and maximizing flow throughout the system while minimizing energy consumption is key. At Maxx Supply, we understand the importance of selecting the right pipe size to achieve optimal flow velocity and efficiency. Join us as we delve into the intricacies of pipe flow velocity by size and uncover strategies to enhance performance in industrial applications.

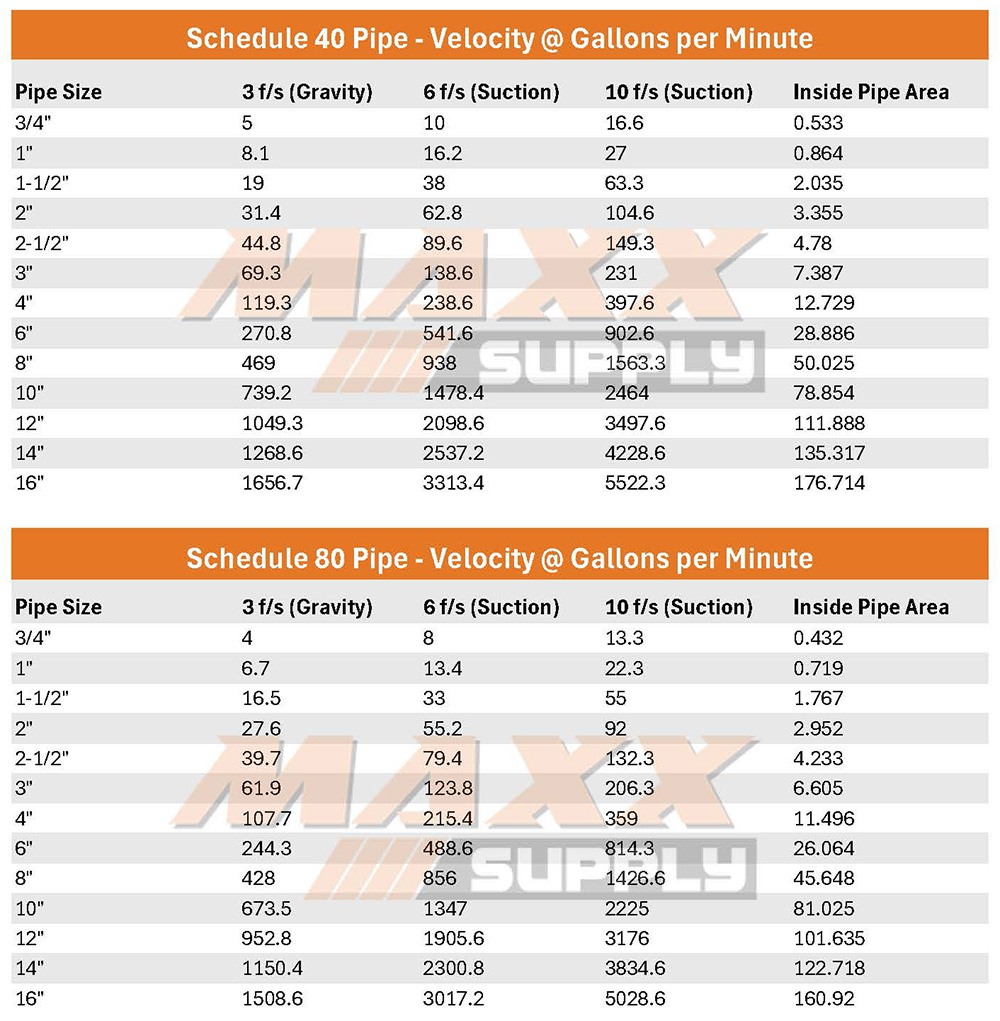

Understanding Pipe Flow Velocity: Pipe flow velocity refers to the speed at which fluid travels through a pipeline. It's a critical parameter that directly impacts the efficiency and effectiveness of fluid transportation systems. The relationship between pipe size and flow velocity is fundamental: larger pipes generally result in lower flow velocities, while smaller pipes lead to higher velocities.

The Importance of Size Selection: Selecting the appropriate pipe size is a balancing act between flow velocity, pressure drop, and system requirements. While larger pipes offer lower flow velocities and reduced frictional losses, they may come with higher initial costs and increased space requirements. Conversely, smaller pipes can accommodate higher flow velocities but may lead to greater pressure drop and energy consumption.

Factors Influencing Size Selection: Several factors influence the selection of pipe size for optimal flow velocity and efficiency:

- Flow Rate: The desired flow rate dictates the minimum required pipe size to achieve the desired velocity without excessive pressure drop.

- Fluid Properties: Viscosity, density, and temperature of the fluid being transported affect flow characteristics and pipe sizing calculations.

- System Constraints: Space limitations, budget constraints, and installation considerations play a significant role in determining the appropriate pipe size.

- Future Expansion: Anticipating future changes in flow requirements can help avoid costly retrofitting by selecting a pipe size that accommodates potential growth.

Strategies for Optimization: To maximize efficiency in fluid transportation systems, consider the following strategies:

- Conduct thorough calculations and simulations to determine the optimal pipe size based on flow requirements and system constraints.

- Utilize flow control devices such as valves and regulators to fine-tune flow velocity and optimize system performance.

- Implement periodic maintenance and inspection protocols to detect and address any issues that may impact flow velocity and efficiency.

- Invest in high-quality pipes and fittings designed to minimize frictional losses and ensure long-term reliability.

Conclusion:

In the quest for efficiency, understanding the relationship between pipe size and flow velocity is paramount. At Maxx Supply, we're committed to helping you navigate the complexities of fluid transportation systems and optimize performance. By mastering pipe flow velocity by size, you can enhance efficiency, reduce operational costs, and ensure the seamless operation of your industrial processes. Unlock the full potential of your systems with Maxx Supply – your partner in fluid dynamics excellence.